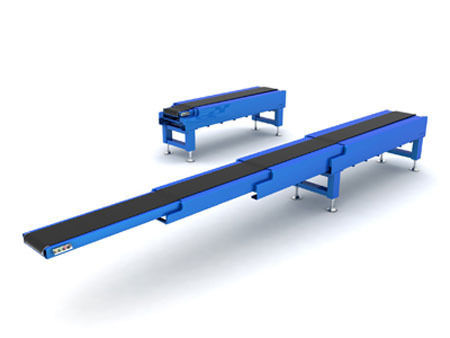

Telescopic Belt Conveyor

Price 1000000.0 INR/ Unit

Telescopic Belt Conveyor Specification

- Belt Type

- PVC Belt

- Surface Finish

- Powder Coated

- Power Source

- Electric

- Thickness

- 3-8 mm Millimeter (mm)

- Features

- Extendable length, Easy operation, Adjustable height

- Material

- Mild Steel

- Type

- Other

- Structure

- Other

- Belt Conveyor

- Flat Belt

- Roller Conveyor

- Other

- Vertical Conveyor

- Other

- Pneumatic Conveyor

- Other

- Resistant Feature

- Other

- Load Capacity

- 50-100 kg/m Kilograms (kg)

- Voltage

- 220-240 V Volt (v)

- Power

- 2.5 kW Horsepower (HP)

- Speed

- 20-40 m/min m/m

- Warranty

- 12 Months

- Usage & Applications

- Loading and Unloading Trucks, Warehouses, Logistics

- Safety Features

- Emergency stop switch, Side guards

- Mobility

- Castor wheels provided

- Operating Temperature

- -10°C to +50°C

- Number of Telescopic Sections

- 3-5 Sections

- Control System

- Panel operated

- Length (Extendable)

- 6-18 meters

- Width

- 600-800 mm

- Installation

- Easy on-site assembly

- Customization

- Available on request

- Noise Level

- <70 dB

Telescopic Belt Conveyor Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 1 Unit Per Month

- Delivery Time

- 4 Week

- Sample Policy

- Contact us for information regarding our sample policy

- Main Domestic Market

- All India

About Telescopic Belt Conveyor

We are an ISO 9001:2008 certified firm engaged in manufacturing, exporting and supplying a wide range of Telescopic Belt Conveyor. These Telescopic Belt Conveyor are manufactured using quality tested components and pioneering techniques by skilled professionals. The provided Telescopic Belt Conveyor can be bought from us in different specification at reasonable rates.

Key Points:

- Longer service life

- Low maintenance

- Easy to install

- Fine finish

Versatile Length and Superior Control

With extendable sections ranging from 6 to 18 meters, the Telescopic Belt Conveyor provides flexibility to handle various truck sizes and loading bay configurations. Operated via an intuitive control panel, users can extend or retract the conveyor as needed, ensuring efficient use of space and time during operations.

Reliable and Safe Operation

Safety is paramount with integrated side guards and an emergency stop switch, all supported by a stable steel frame. The conveyors noise level remains below 70 dB, making it suitable for busy work environments. Its powder-coated, corrosion-resistant surface ensures durability in demanding industrial settings.

Effortless Mobility and Easy Assembly

Designed with castor wheels, the conveyor is easily moved between bays or storage areas. On-site assembly is straightforward, reducing downtime and simplifying deployment. Adjustable height and customizable options cater to specific operational requirements.

FAQs of Telescopic Belt Conveyor:

Q: How is the Telescopic Belt Conveyor installed on-site?

A: The conveyor is designed for easy on-site assembly, with clear instructions and modular components allowing for quick setup without specialized tools or extensive downtime.Q: What are the main benefits of using a telescopic belt conveyor in warehouse operations?

A: Using a telescopic belt conveyor streamlines loading and unloading processes, increases efficiency, reduces manual labor, and minimizes handling times, all while ensuring operator safety.Q: When should I consider customizing the conveyor, and what options are available?

A: Customization is ideal when specific length, width, or features are required for unique applications. Options include adjusting conveyor length, belt width, height, and additional safety or control features, available upon request.Q: Where can this conveyor be effectively utilized?

A: This conveyor is well-suited for truck loading and unloading at warehouses, logistics centers, and distribution hubs, enhancing efficiency in high-volume environments.Q: What safety measures are incorporated in the design?

A: Key safety features include side guards along the conveyor, an emergency stop switch, and a stable steel frame, all designed to minimize risk during operation.Q: How does the control system operate and what power is required?

A: The conveyor is operated via a panel control system, running on a 220-240V electric supply with a 2.5 kW power rating, ensuring reliable and consistent performance.Q: What is the process for maintenance and ensuring longevity?

A: Routine inspections, belt cleaning, and checking fasteners ensure optimal performance. The powder-coated, corrosion-resistant steel frame and PVC belt enhance durability and reduce maintenance requirements.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Belt Conveyor Category

Rubber Belt Conveyor

Price 22000.0 INR / Piece

Minimum Order Quantity : 1 Piece

Belt Type : Smooth, Cleated or Chevron Rubber Belt

Voltage : 220V / 380V Volt (v)

Material : Mild Steel (MS), Stainless Steel (SS), with Rubber Belt

Structure : Other

Incline Belt Conveyor

Price 75000.0 INR / Piece

Minimum Order Quantity : 1 Piece

Belt Type : Rough Top PVC Belt

Voltage : 220415 V Volt (v)

Material : Mild Steel, PVC Belt

Structure : Incline

Belt Conveyor System

Price 35000.0 INR / Piece

Minimum Order Quantity : 1 Piece

Belt Type : Flat belt

Voltage : 220V / 380V / 415V AC (as per order) Volt (v)

Material : Rubber, PVC, PU for belt; MS or SS for frame

Structure : Other

Pipe Conveyor

Price 400000.0 INR / Piece

Minimum Order Quantity : 1 Piece

Belt Type : Enclosed circular pipe belt

Voltage : Typically 220V/380V, customizable Volt (v)

Material : Highgrade steel framework with rubber/polymer belt

Structure : Other

Send Inquiry

Send Inquiry