Pipe Conveyor

Price 400000.0 INR/ Piece

Pipe Conveyor Specification

- Thickness

- sBelt thicknes typically 8-18 mm Millimeter (mm)

- Surface Finish

- Powder coated/galvanized

- Belt Type

- Enclosed circular pipe belt

- Power Source

- Electric

- Features

- Dust-tight, curved conveying, environmentally friendly, reduces spillage

- Material

- High-grade steel framework with rubber/polymer belt

- Type

- Other

- Structure

- Other

- Belt Conveyor

- Other

- Roller Conveyor

- Other

- Vertical Conveyor

- Other

- Pneumatic Conveyor

- Other

- Resistant Feature

- Other

- Load Capacity

- Variable, up to several tons per hour depending on configuration Kilograms (kg)

- Voltage

- Typically 220V/380V, customizable Volt (v)

- Power

- Depends on motor and conveyor length, generally 5-75 KW Ampere (amp)

- Speed

- Adjustable, usually 0.5 to 3.15 m/s m/s

- Usage & Applications

- Bulk material transport in mining, cement, power, and port industries

- Maintenance

- Low maintenance due to enclosed system

- Belt Material

- Rubber/Polymer composite, reinforced

- Conveyor Inclination

- Up to 30 degrees

- Belt Width

- 150 mm to 600 mm (depends on model)

- Environmental Compliance

- Meets ISO and local dust/emission standards

- Noise Level

- Low, typically less than 75 dB

- Installation

- Outdoor/indoor as per requirement

- Belt Speed Control

- VFD control available

- Max Conveyor Length

- Up to 3 km or as required

- Conveyor Cover

- Fully enclosed design for environmental protection

Pipe Conveyor Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 1 Piece Per Month

- Delivery Time

- 7 Days

- Sample Policy

- Contact us for information regarding our sample policy

- Main Domestic Market

- All India

About Pipe Conveyor

We are an ISO 9001:2008 certified firm engaged in manufacturing, exporting and supplying a wide range of Pipe Belt Conveyor. These Pipe Belt Conveyor are manufactured using quality tested components and pioneering techniques by skilled professionals. The provided Pipe Belt Conveyor can be bought from us in different specification at reasonable rates.

Key Points:

- Longer service life

- Low maintenance

- Easy to install

- Fine finish

Efficient Enclosed Conveying

Pipe Conveyors are engineered for dust-tight, curved conveying, minimizing material spillage and reducing environmental impact. Their enclosed design is perfect for transporting bulk materials across long distances and through complex routes, making them suitable for operations where cleanliness, safety, and efficiency are critical.

Robust Construction & Adaptability

Manufactured using high-grade steel and a reinforced rubber/polymer composite belt, the Pipe Conveyor withstands harsh, corrosive, or high-temperature environments. Its modular design allows customizable configurations, supporting variable load capacities, inclinations up to 30 degrees, and optional vertical conveying for tailored applications.

FAQs of Pipe Conveyor:

Q: How does a pipe conveyor operate and what makes it distinct from conventional belt conveyors?

A: A pipe conveyor operates by shaping the conveyor belt into a closed tube (pipe) using idler rollers. This design prevents material spillage, enables curved routing, and provides superior environmental protection compared to traditional open belt conveyors.Q: What are the primary benefits of using a pipe conveyor system in industrial applications?

A: Key benefits include dust-tight, fully enclosed material transport, low noise emissions (below 75 dB), reduced maintenance due to enclosure, flexible routing over obstacles, and compliance with environmental standards, making them ideal for bulk handling in challenging settings.Q: Where can pipe conveyors be installed and are they suitable for outdoor use?

A: Pipe conveyors can be installed both indoors and outdoors due to their robust, weather-resistant structure. Their enclosed design protects materials from wind and rain, ensuring reliable operation in varied environments.Q: What materials and applications are suitable for pipe conveyor systems?

A: These conveyors are well-suited for bulk materials like coal, cement clinker, minerals, and ores. Common applications include mining sites, cement plants, power stations, and port facilities where dust control and spillage reduction are essential.Q: How is the speed and power of the pipe conveyor controlled and customized?

A: Speed is adjustable via VFD (Variable Frequency Drive) control, typically ranging from 0.5 to 3.15 m/s. Power requirements depend on conveyor length, load, and inclination and generally range from 5 to 75 KW. Both voltage and configuration can be customized to project needs.Q: When should a vertical pipe conveyor be considered, and what is the process for customization?

A: Vertical pipe conveyors are ideal when material transport requires steep inclines or space-saving vertical routing. Custom vertical solutions are designed in consultation with customers, considering material type, capacity, and site layout.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

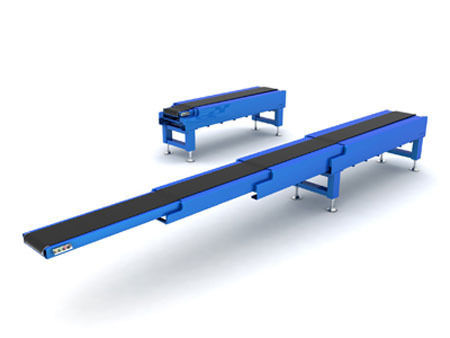

More Products in Belt Conveyor Category

Heavy Duty Conveyor Systems

Price 50000.0 INR / Piece

Minimum Order Quantity : 1 Piece

Structure : Other

Speed : 0.5 m/s to 2.5 m/s (variable speed drives available) m/s

Power : 1.5 kW to 15 kW depending on configuration Horsepower (HP)

Belt Type : Modular, flat, or chevron belts

Rubber Belt Conveyor

Price 22000.0 INR / Piece

Minimum Order Quantity : 1 Piece

Structure : Other

Speed : 0.8 2.5 m/s m/s

Power : 0.75 15 kW Watt (w)

Belt Type : Smooth, Cleated or Chevron Rubber Belt

Telescopic Belt Conveyor

Price 1000000.0 INR / Unit

Minimum Order Quantity : 1 Unit

Structure : Other

Speed : 2040 m/min m/m

Power : 2.5 kW Horsepower (HP)

Belt Type : PVC Belt

Incline Belt Conveyor

Price 75000.0 INR / Piece

Minimum Order Quantity : 1 Piece

Structure : Incline

Speed : 0.5 2 m/s m/s

Power : 0.75 5 HP Watt (w)

Belt Type : Rough Top PVC Belt

Send Inquiry

Send Inquiry