Garland Carrying Idler Roller

Price 649.0 INR/ Piece

MOQ : 500 Pieces

Garland Carrying Idler Roller Specification

- Thickness

- 3.5 Millimeter (mm)

- Belt Type

- Rubber Belt

- Surface Finish

- Powder Coating/Paint

- Power Source

- Eletric

- Usage

- coal, Mining, Aggregates, Industrial Application

- Material

- Mild Steel

- Type

- Roller Conveyor

- Size

- 60-219 mm

- Structure

- Roller

- Weight

- 9.5 Kilograms (kg)

- Color

- White

- Vertical Conveyor

- Other

- Length

- 1200 Millimeter (mm)

- Width

- 3650 Millimeter (mm)

- Pneumatic Conveyor

- Other

- Resistant Feature

- Other

- Load Capacity

- 1250 Kilograms (kg)

- Voltage

- 240/320/415 Volt (v)

- Power

- 5.5-25 KW Watt (w)

- Speed

- 3.5 m/s

- Warranty

- 12 Months

- Usage & Applications

- Bulk Material Handling

Garland Carrying Idler Roller Trade Information

- Minimum Order Quantity

- 500 Pieces

- Delivery Time

- 24 Days

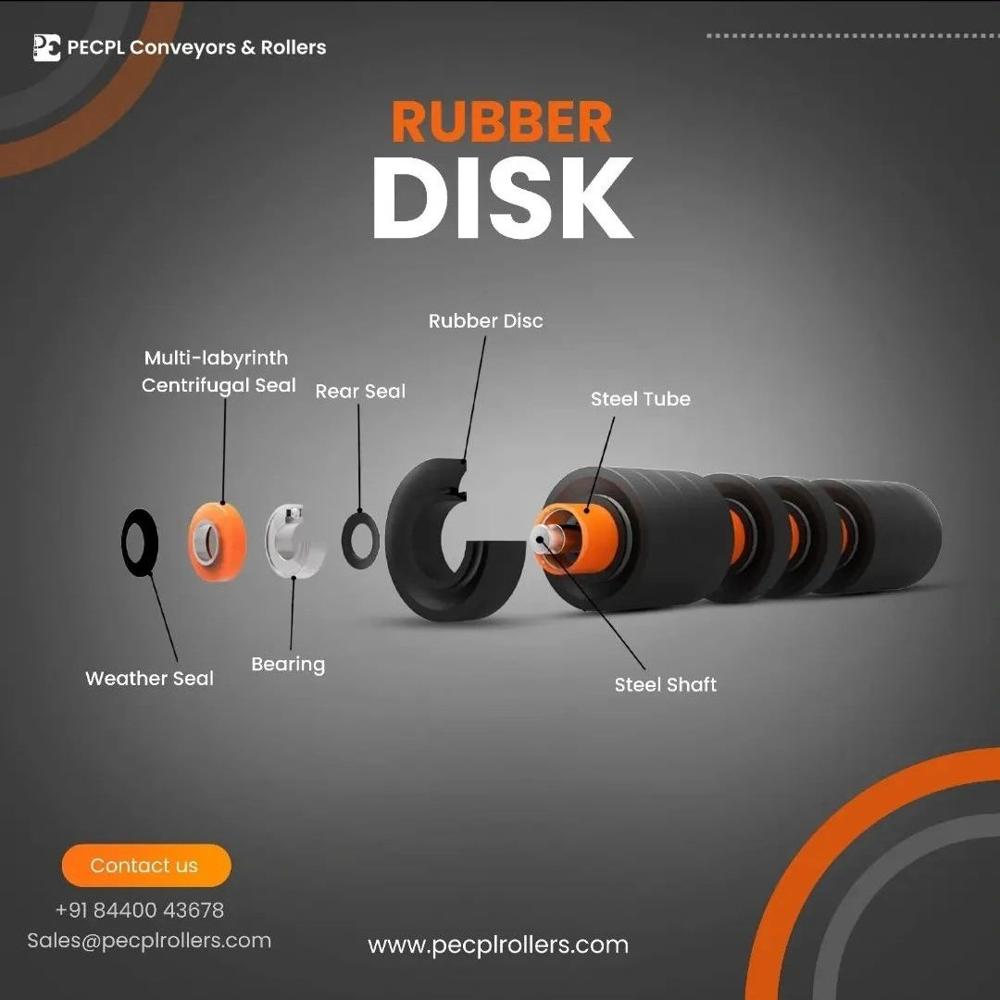

About Garland Carrying Idler Roller

With our experience, knowledge and efforts, we are able to supply an exclusive range of Garland Carrying Idler Roller, that is used to support the conveyor belt. The offered range is made by using the top grade quality material and modern techniques. We assure you to provide the seamless finish and unmatched quality. Our company is providing the range of Garland Carrying Idler Roller at market leading prices.

Features of Garland Carrying Idler Roller:

- Easy installation

- Hassle free operation

- Sturdy design

Purpose-Built Durability for Heavy-Duty Operations

Designed to withstand the rigorous demands of coal and aggregate handling, this garland carrying idler roller features a 3.5 mm thick mild steel build and powder coating/paint for extended lifespan. Its reliable structure ensures seamless integration into conveyor systems operating in challenging industrial environments.

Enhanced Handling and Performance

With adjustable sizes (60-219 mm) and a significant width of 3650 mm, the roller accommodates various material types and conveyor belt widths. Efficient power consumption (5.525 KW) and robust load capacity help optimize productivity for bulk material transport.

FAQs of Garland Carrying Idler Roller:

Q: How is the Garland Carrying Idler Roller installed within conveyor systems?

A: The Garland Carrying Idler Roller is designed to be easily integrated into roller conveyor systems using standard mounting brackets and fittings. Installation should be carried out by professionals familiar with conveyor assembly, ensuring secure attachment to support bulk material movement.Q: What are the key benefits of using this idler roller for bulk material handling?

A: This idler roller delivers high load capacity (up to 1250 kg), corrosion-resistant surface finish, compatibility with various belt sizes, and reliable performance across coal, mining, aggregate, and industrial applications resulting in reduced maintenance and improved operational efficiency.Q: When should this idler roller be replaced or serviced?

A: Regular inspections should be conducted as part of routine conveyor maintenance. Replacement or servicing is recommended if you notice excessive wear, noise, decreases in performance, or at the end of its 12-month warranty period, whichever occurs first.Q: Where can I purchase the Garland Carrying Idler Roller in India?

A: The Garland Carrying Idler Roller is available through leading exporters, manufacturers, and suppliers specializing in bulk material handling equipment across India.Q: What is the process for handling large volumes of materials with this conveyor roller?

A: Materials are loaded onto the conveyors rubber belt, which is supported and moved by the idler rollers. The rollers design ensures smooth, efficient transport of bulk materials such as coal, aggregates, and similar substances along the conveyor path.Q: How does the white powder coating or paint help maintain the rollers quality?

A: The powder coating or paint provides the roller with resistance to corrosion and abrasive wear, thereby extending its lifespan and ensuring consistently high performance even in harsh industrial settings.Q: What types of power sources are compatible with this idler roller?

A: The idler roller operates with an electric power source, accepting input voltages of 240V, 320V, and 415V, making it suitable for a variety of industrial electrical setups.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Conveyor Idler and Roller Category

Conveyor Guide Roller

Price 450.0 INR / Piece

Minimum Order Quantity : 500 Pieces

Thickness : 3.5 Millimeter (mm)

Color : Orange/Customised

Voltage : 515KW Volt (v)

Load Capacity : 1250 Kilograms (kg)

Conveyor Impact Idler

Price 698.0 INR / Piece

Minimum Order Quantity : 500 Pieces

Thickness : 4.5 Millimeter (mm)

Color : Black

Voltage : 240 Volt (v)

Load Capacity : 1550 Kilograms (kg)

Send Inquiry

Send Inquiry