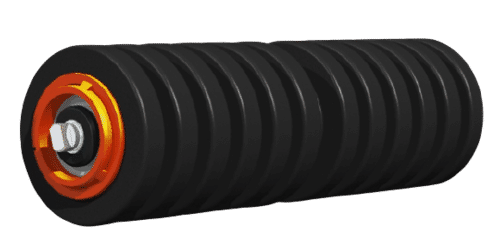

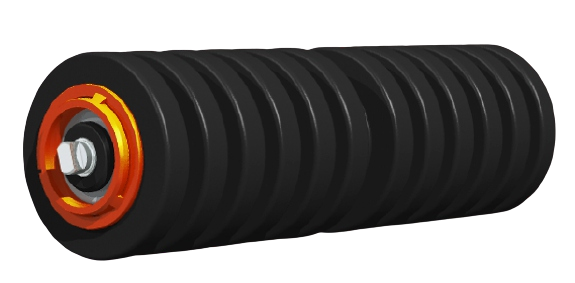

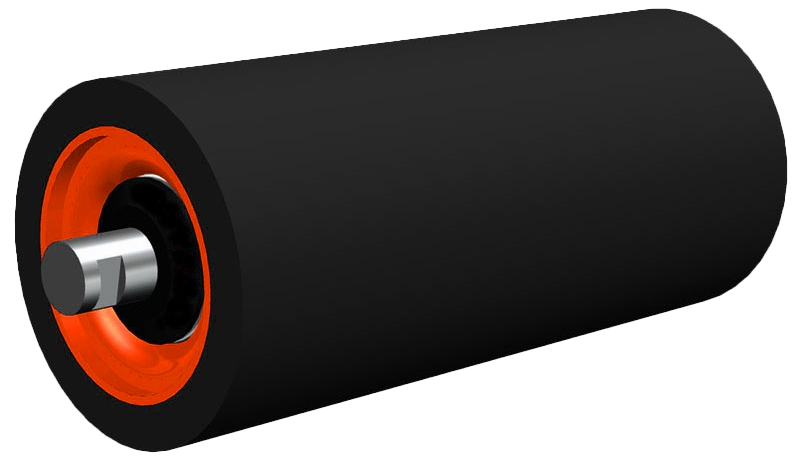

Conveyor Impact Idler

Price 698.0 INR/ Piece

Conveyor Impact Idler Specification

- Surface Finish

- Sore A Hardness 55-70

- Thickness

- 4.5 Millimeter (mm)

- Material

- Stainless Steel

- Type

- Roller Conveyor

- Structure

- Other

- Color

- Black

- Length

- 800 Millimeter (mm)

- Load Capacity

- 1550 Kilograms (kg)

- Voltage

- 240 Volt (v)

- Power

- 5-15kw Watt (w)

- Speed

- 3.5 m/s

Conveyor Impact Idler Trade Information

- Minimum Order Quantity

- 500 Pieces

- FOB Port

- NAVA Shiva

- Payment Terms

- Telegraphic Transfer (T/T), Letter of Credit (L/C)

- Supply Ability

- 20000 Pieces Per Month

- Delivery Time

- 14 Days

- Sample Policy

- Free samples available with shipping and taxes paid by the buyer

- Main Export Market(s)

- Asia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- Main Domestic Market

- All India

About Conveyor Impact Idler

Our Heavy Duty Conveyor Rollers are built to withstand the toughest conditions in the mining industry. These rollers are made with high-quality materials, such as steel and rubber, to ensure maximum durability and longevity. They are designed to be low maintenance and easy to install.

Here are some key specifications of our Heavy Duty Conveyor Rollers:

1. Load Capacity: Our rollers can handle a load capacity of up to 10,000 kg per roller.

2. Bearing Type: We use sealed-for-life bearings, which require no lubrication, reducing maintenance requirements.

3. Roller Diameter: Our rollers are available in various diameters, ranging from 89mm to 219mm.

4. Roller Length: We offer rollers in lengths of up to 3000mm to accommodate different conveyor belt widths.

5. Material: Our rollers are made with high-quality steel and rubber, providing excellent resistance to wear and tear.

6. Customization: We can customize our rollers to meet the specific requirements of your mining operations.

Our Heavy Duty Conveyor Rollers are designed to reduce downtime and increase productivity in your mining operations. With our reliable and durable rollers, you can rest assured that your conveyor system will operate smoothly and efficiently.

For more information on our Heavy Duty Conveyor Rollers or to request a quote, please contact us today. We look forward to working with you.

Durable Construction & High Load Capacity

Engineered from high-grade stainless steel, our Conveyor Impact Idler resists wear and supports heavy loads up to 1550 kilograms. With its 4.5 mm thick roller and 800 mm length, this idler offers stability and longevity, even under continuous operation. The black finish and Sore A Hardness rating further enhance durability, reducing downtime in demanding environments.

Reliable Performance for Material Handling

With a speed of 3.5 m/s and a 515 kW power range, our conveyor idler ensures smooth, continuous material transfer. Designed to absorb impacts, it preserves the integrity of both the conveyor belt and the transported materials. This makes it ideal for bulk handling in mining, logistics, and various industrial sectors, where reliability is crucial.

FAQs of Conveyor Impact Idler:

Q: How is the Conveyor Impact Idler installed in a production line?

A: The Conveyor Impact Idler is installed at impact points along conveyor belts, typically where heavy or abrasive materials are loaded. Its standard 800 mm length and robust mounting features allow for straightforward incorporation into new or existing roller conveyor systems.Q: What materials are suitable to be conveyed using this idler?

A: This idler is designed for a wide range of bulk and heavy materials, including ores, coal, aggregate, and other industrial raw materials. Its stainless steel build with Sore A Hardness 55-70 ensures effective absorption of high impact forces, protecting both the belt and the conveyed products.Q: When should the impact idler be replaced or maintained?

A: Regular inspections are advised, especially in high-throughput environments. Replacement or maintenance is typically needed if there is significant wear, unusual noise, or decreased performance. Following the manufacturers schedule ensures longevity and optimal functioning.Q: Where can the Conveyor Impact Idler be used effectively?

A: It is ideally used in industries such as mining, quarrying, bulk material handling, and logistics, especially at transfer or loading zones within conveyors where material impact is highest.Q: What process is used to manufacture this idler?

A: The Conveyor Impact Idler is produced through precision machining and assembly using stainless steel for durability. The rollers are finished to a Sore A Hardness of 55-70, providing resilience against impact. Stringent quality checks ensure every unit meets load and performance requirements.Q: How does using this idler benefit a conveyor system?

A: Utilizing this impact idler minimizes conveyor belt wear and absorbs shock loads, reducing the risk of damage to both the belt and materials. This extends belt life, lowers maintenance costs, and promotes consistent system performance.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Conveyor Idler and Roller Category

Conveyor Guide Roller

Price 450.0 INR / Piece

Minimum Order Quantity : 500 Pieces

Thickness : 3.5 Millimeter (mm)

Load Capacity : 1250 Kilograms (kg)

Belt Type : Rubber Belt/PCV

Surface Finish : Podwer Coated/Paint

Garland Carrying Idler Roller

Price 649.0 INR / Piece

Minimum Order Quantity : 500 Pieces

Thickness : 3.5 Millimeter (mm)

Load Capacity : 1250 Kilograms (kg)

Belt Type : Rubber Belt

Surface Finish : Powder Coating/Paint

Send Inquiry

Send Inquiry