Roller Idlers

Price 1600.0 INR/ Piece

Roller Idlers Specification

- Surface Finish

- Powder Coating/Paint

- Features

- Standard

- Thickness

- 3.5 Millimeter (mm)

- Power Source

- Eletric

- Belt Type

- Rubber Belt

- Usage

- Belt Conveyor

- Material

- Mild Steel

- Type

- Belt Conveyor

- Size

- 60-219 mm

- Structure

- Roller

- Height

- 700 Millimeter (mm)

- Belt Conveyor

- Troughed Belt

- Product Type

- Conveyor Idler

- Weight

- 8.5 Kilograms (kg)

- Roller Conveyor

- Other

- Vertical Conveyor

- Reciprocating Vertical Conveyor

- Color

- White/Orange/Customised

- Width

- 600-3000 mm Millimeter (mm)

- Pneumatic Conveyor

- Other

- Length

- 1200 Millimeter (mm)

- Resistant Feature

- Other

- Load Capacity

- 1250 Kilograms (kg)

- Voltage

- 240/415 Volt (v)

- Power

- 5.5-15kw Watt (w)

- Speed

- 3.5 m/s

- Warranty

- 12 Months

- Usage & Applications

- Bulk Handling

Roller Idlers Trade Information

- Minimum Order Quantity

- 50 Pieces

- Payment Terms

- Cash Advance (CA), Cash in Advance (CID), Delivery Point (DP), Telegraphic Transfer (T/T)

- Supply Ability

- 15000 Pieces Per Month

- Delivery Time

- 22 Days

- Sample Available

- No

- Sample Policy

- Within a certain price range free samples are available

- Packaging Details

- Wooden box, Iron Box

- Main Export Market(s)

- Asia, Middle East, Africa, Australia, North America

- Main Domestic Market

- All India

- Certifications

- ISO, TUV, IEC

About Roller Idlers

Roller Idlers

Being in this domain since 2005, we have been affianced in manufacturing, exporting and supplying a premium range of Roller Idlers. These idlers are manufactured using top quality components and innovative techniques by ingenious professionals. Offered idlers are used for rotating conveyor belts in various manufacturing and packaging industries. Furthermore, our prestigious clients can buy these Roller Idlers from us at rock bottom rates within stipulated time frame.

Key Points:

- Robust construction

- Highly durable

- Optimum performance

- Quick installation

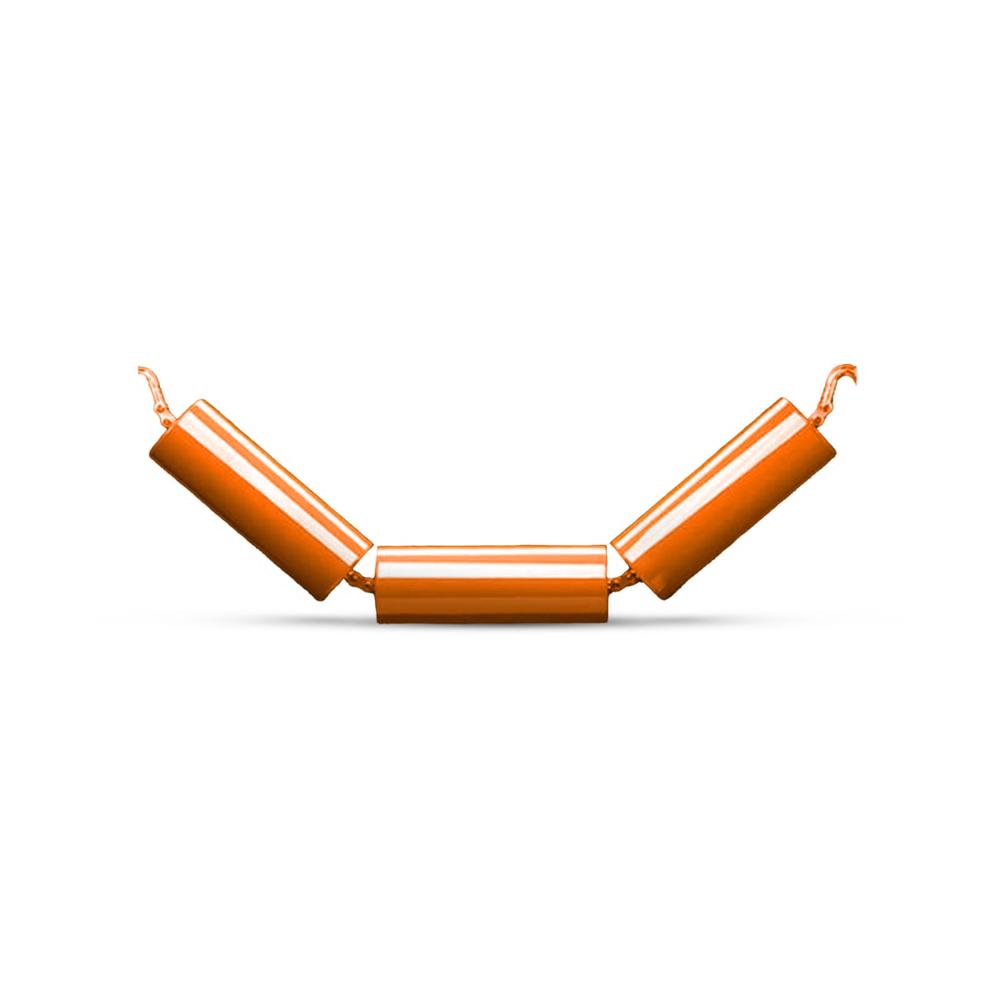

Built for Bulk Handling Efficiency

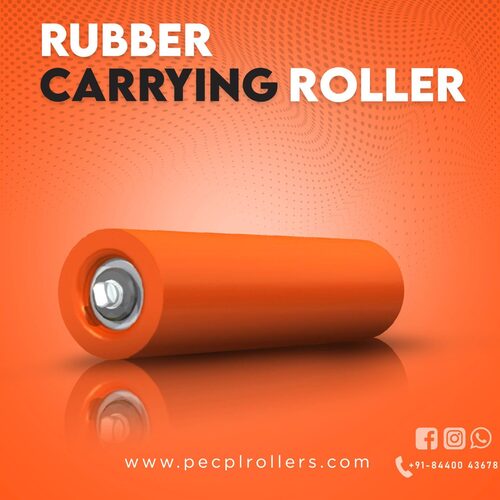

Designed to handle heavy-duty applications in bulk material handling, our Roller Idlers are compatible with rubber belt conveyors, making them ideal for industries moving substantial loads. The robust construction and powder-coated or painted finish ensure longevity and low maintenance across a range of environments.

Customizable for Your Conveyor Needs

Choose from sizes between 60 to 219 mm in diameter, belt widths from 600 to 3000 mm, and a variety of colors including white, orange, or tailored to your specifications. Our roller idlers are designed to fit seamlessly with standard troughed belt and vertical reciprocating conveyors for versatility and performance.

FAQs of Roller Idlers:

Q: How are these roller idlers installed on a belt conveyor system?

A: Roller idlers are installed along the conveyor frame at specific intervals to support the rubber belt and load. Mounting brackets are aligned to the conveyors frame, and the idler is secured using standardized fittings. Proper alignment ensures smooth movement and extends belt life.Q: What types of conveyors are compatible with these roller idlers?

A: These idlers are engineered for troughed belt conveyors and reciprocating vertical conveyors. Their structure and finish suit bulk handling applications, making them commonly used in industries such as mining, agriculture, and logistics where rubber belt solutions are preferred.Q: When is it advisable to replace a roller idler?

A: Roller idlers should be inspected periodically. Replace them if you notice excessive wear, abnormal noise, uneven rotation, or visible damage. Regular maintenance helps maintain conveyor efficiency and minimizes downtime.Q: Where are your roller idlers manufactured and supplied from?

A: We are an Indian exporter, manufacturer, and supplier. Our roller idlers are manufactured using high-quality mild steel and rigorous quality control processes at our advanced facilities in India, with supply available nationwide.Q: What is the process for ordering a customized roller idler?

A: To customize your roller idlers, specify your preferred color, size (between 60219 mm), length, and surface finish (powder coating or paint). Reach out to our sales team who will guide you through selection, pricing, and delivery timelines to ensure your requirements are fully met.Q: How does the powder coating or paint finish benefit the roller idler?

A: Powder coating and paint enhance the roller idlers resistance to corrosion, abrasion, and harsh environmental factors. This finish prolongs the idlers working life, reduces the need for frequent replacements, and ensures reliable performance over extended periods.Q: What are the primary usage and benefits of these roller idlers?

A: These roller idlers are primarily used in belt conveyor systems for bulk handling. Their robust design supports heavy loads (up to 1250 kg), delivers smooth belt operation at speeds up to 3.5 m/s, and requires minimal maintenance, leading to increased uptime and operational efficiency.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Idler Roller Category

Bracket Roller Idlers

Price 1500.0 INR / Set

Minimum Order Quantity : 100 Sets

Material : Steel

Structure : Other

Type : Belt Conveyor

Warranty : 12 Months

Idler Roller

Price 3000.0 INR / Set

Minimum Order Quantity : 50 Sets

Material : Mild Steel (MS) with powder coating

Structure : Other

Type : Belt Conveyor

Warranty : 12 Months

Garland Roller Idlers

Price 2500.0 INR / Set

Minimum Order Quantity : 50 Sets

Material : Heavyduty steel, mild steel, stainless steel with powder or painted coating

Structure : Other

Type : Belt Conveyor

Warranty : 12 months

Heavy Duty Conveyor Idler Rollers

Price 600 INR / Set

Minimum Order Quantity : 50 Sets

Material : Mild Steel, Stainless Steel ,Rubber ,UHMWPE ,HDPE , Plastic

Structure : Roller

Type : Other

Warranty : 12 Months

Send Inquiry

Send Inquiry