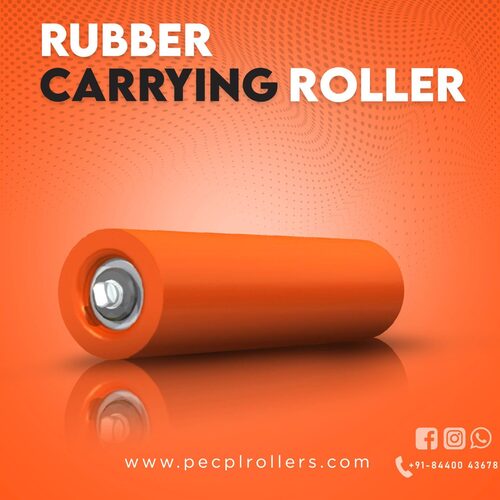

Idler Roller

Price 3000.0 INR/ Set

Idler Roller Specification

- Surface Finish

- Glossy, Powder Coated

- Thickness

- 3-5 mm (as per design) Millimeter (mm)

- Features

- Heavy Duty, Low Maintenance, Smooth Rotation, Rustproof

- Power Source

- Eletric

- Belt Type

- Rubber Belt

- Usage

- Belt Conveyor

- Material

- Mild Steel (MS) with powder coating

- Type

- Belt Conveyor

- Size

- 60-219 mm

- Structure

- Other

- Belt Conveyor

- Troughed Belt

- Roller Conveyor

- Other

- Color

- Customised, Standard

- Resistant Feature

- Other

- Load Capacity

- Up to 200 kg per roller Kilograms (kg)

- Voltage

- 240 Volt (v)

- Power

- 5.5-15 Horsepower (HP)

- Speed

- 3.5/2.5/5.5/7.5 m/s

- Warranty

- 12 Months

- Usage & Applications

- Used in conveyor systems for material handling, transportation in warehouses, manufacturing, and assembly lines.

Idler Roller Trade Information

- Minimum Order Quantity

- 50 Sets

- Supply Ability

- 15000 Sets Per Month

- Delivery Time

- 7 Days

- Sample Available

- No

- Sample Policy

- Contact us for information regarding our sample policy

- Main Domestic Market

- All India

About Idler Roller

Idler RollerSince our inception in the year 2005, we have been engaged in offering a wide array of Idler Roller. This roller is manufactured using top-notch quality components and pioneering techniques by our skilled professionals. Offered roller finds its extensive use in rolling conveyor belt in numerous packaging industries, cement plants,stone crushers etc. Additionally, this roller is highly cherished among clients due to its rugged construction and fine finish. This Idler Roller can be purchased from us at pocket friendly rates.

Key Points:

- Low maintenance

- Easy to install

- Enhanced durability

- Smooth operation

Customizable Dimensions for Versatile Applications

The Idler Roller offers flexibility in both diameter and length, accommodating various demands in material handling and conveyor system designs. Choose from diameters of 50 mm to 89 mm and roller lengths ranging from 300 mm to 1200 mm to fit the specific requirements of industrial warehouses, assembly lines, and manufacturing units.

Durable Build and Corrosion Resistance

Constructed with mild steel and finished in glossy powder coating, these rollers are designed for heavy duty and long-lasting performance. Their corrosion-resistant feature ensures reliable operation in demanding environments, withstanding ambient temperatures from -10C to 80C. Maintenance remains minimal due to the sealed ball bearing and rustproof exterior.

Efficient Installation and Smooth Operation

The idler rollers are engineered for quick installation and easy replacement. They are compatible with belt and roller conveyor systems, and support flat belt applications. Thanks to their low noise operation and smooth rotation, they promote a quieter workspace and increase operational efficiency in Indian industries.

FAQs of Idler Roller:

Q: How is the Idler Roller installed on conveyor systems?

A: The Idler Roller features a user-friendly design with tube shaft ends, making installation and replacement straightforward. Simply align the roller with the conveyor frame and secure it using standard fasteners. This process allows for quick integration into both belt and roller conveyors.Q: What are the benefits of the sealed ball bearing used in the Idler Roller?

A: Sealed ball bearings ensure the roller rotates smoothly while keeping out dust and moisture, resulting in low noise operation and minimal maintenance. This increases the rollers life span and reliability, crucial for high-traffic conveyor systems.Q: When should I consider customizing the rollers dimensions?

A: Customization is recommended when the conveyor system requires specific roller diameters (between 50 mm to 89 mm) or lengths (300 mm to 1200 mm) for optimal performance in handling materials of various sizes or weights. Custom sizing improves operational efficiency and load distribution.Q: Where can the Idler Roller be used within material handling operations?

A: Idler Rollers are commonly applied in warehouses, manufacturing units, assembly lines, and any setting where conveyor systems are used for transporting goods. Their compatibility with flat belt and roller conveyors makes them suitable for diverse industrial environments across India.Q: What is the process for replacing a worn Idler Roller?

A: To replace a worn Idler Roller, first stop the conveyor system and secure the area. Remove the fasteners holding the roller, slide out the old unit, and insert the new roller, ensuring proper alignment. Reattach all fittings and test for smooth rotation before resuming operation.Q: How does the Idler Roller contribute to a low maintenance system?

A: The combination of sealed ball bearings, corrosion-resistant powder coating, and high-quality steel shaft reduces the frequency of repairs and part replacements. These features collectively decrease downtime and maintenance costs, ensuring uninterrupted material flow.Q: What advantages does powder coating provide for Idler Rollers?

A: Powder coating enhances the rollers resistance to corrosion and wear, contributing to a glossy, rustproof surface. This finish maintains the rollers appearance and functionality over prolonged usage, especially in environments prone to moisture or chemicals.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Idler Roller Category

Roller Idlers

Price 1600.0 INR / Piece

Minimum Order Quantity : 50 Pieces

Warranty : 12 Months

Material : Mild Steel

Structure : Roller

Type : Belt Conveyor

Bracket Roller Idlers

Price 1500.0 INR / Set

Minimum Order Quantity : 100 Sets

Warranty : 12 Months

Material : Steel

Structure : Other

Type : Belt Conveyor

Garland Roller Idlers

Price 2500.0 INR / Set

Minimum Order Quantity : 50 Sets

Warranty : 12 months

Material : Heavyduty steel, mild steel, stainless steel with powder or painted coating

Structure : Other

Type : Belt Conveyor

Heavy Duty Conveyor Idler Rollers

Price 600 INR / Set

Minimum Order Quantity : 50 Sets

Warranty : 12 Months

Material : Mild Steel, Stainless Steel ,Rubber ,UHMWPE ,HDPE , Plastic

Structure : Roller

Type : Other

Send Inquiry

Send Inquiry