Bracket Roller Idlers

Price 1500.0 INR/ Set

Bracket Roller Idlers Specification

- Features

- Customized design

- Belt Type

- Rubber Belt

- Surface Finish

- Powder coating/paint

- Thickness

- 3.5 Millimeter (mm)

- Power Source

- Eletric

- Usage

- Belt Conveyor

- Material

- Steel

- Type

- Belt Conveyor

- Size

- 40-219mm

- Structure

- Other

- Product Type

- Heavy duty Conveyor Roller

- Weight

- 12 Kilograms (kg)

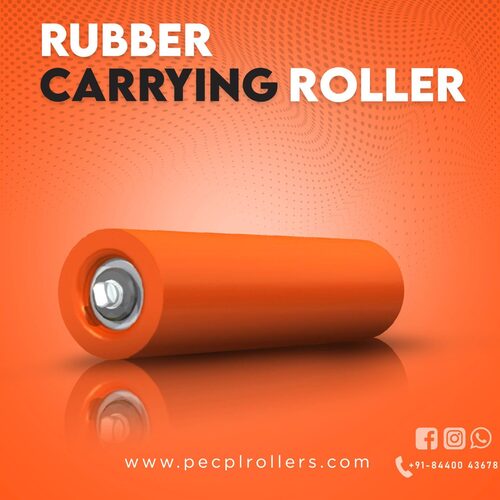

- Color

- Orange

- Length

- 180- 3000mm Millimeter (mm)

- Pneumatic Conveyor

- Other

- Resistant Feature

- Other

- Load Capacity

- 6000 Kilograms (kg)

- Voltage

- 240 Volt (v)

- Power

- 240 Volt (v)

- Speed

- 3.5 m/s

- Warranty

- 12 Months

- Usage & Applications

- Belt Conveyor

Bracket Roller Idlers Trade Information

- Minimum Order Quantity

- 100 Sets

- Supply Ability

- 15000 Sets Per Month

- Delivery Time

- 7 Days

- Sample Available

- No

- Sample Policy

- Contact us for information regarding our sample policy

- Main Domestic Market

- All India

About Bracket Roller Idlers

Bracket Roller Idlers

Backed by a team of skilled professionals, we have been engaged in offering a wide array of Bracket Roller Idlers. These idlers are manufactured under the guidance of skilled professionals using top-notch quality components and pioneering techniques. Offered idlers are used in conveyor belts for providing rotation to it. Furthermore, our valuable clients can buy these Bracket Roller Idlers from us at nominal rates within committed delivery time.

Key Points:

- High durability

- Low maintenance

- Rust resistance

- Easy to install

Engineered for Heavy-Duty Performance

Designed to endure rigorous industrial environments, Bracket Roller Idlers boast a substantial load capacity of up to 6,000 kg. Their steel construction and robust powder coating or paint finish ensure longevity, even in challenging working conditions. These idlers offer reliable support for belt conveyor systems, enhancing operational efficiency for various material handling applications.

Versatile and Customizable Solutions

With a fully customizable range from 40 mm to 219 mm in diameter and lengths up to 3,000 mm, these idlers cater to diverse project needs. The ability to customize dimensions and features ensures compatibility with existing conveyor setups, providing seamless integration for manufacturers and exporters alike.

FAQs of Bracket Roller Idlers:

Q: How are Bracket Roller Idlers installed in a belt conveyor system?

A: Bracket Roller Idlers are mounted within the conveyor frame at specific intervals, supporting the rubber belt and ensuring smooth material movement. Installation involves aligning the idlers under the belt and securing them with brackets, following the conveyor systems design specifications.Q: What types of belts are compatible with these idlers?

A: These idlers are specifically designed for use with rubber belt conveyors. Their robust steel construction and surface finish make them suitable for handling various materials under demanding conditions.Q: When should I consider replacing my Bracket Roller Idlers?

A: Replacement is recommended if you notice excessive wear, abnormal noise, belt misalignment, or inconsistent material movement. Regular maintenance checks help identify issues early; typically, the 12-month warranty provides coverage for manufacturing defects during initial use.Q: Where are Bracket Roller Idlers commonly used?

A: These idlers are utilized across industries such as mining, logistics, manufacturing, and agricultural processing plants in India and worldwide, wherever belt conveyor systems are integral to operations.Q: What is the process for ordering customized Bracket Roller Idlers?

A: To order, you can specify diameter, length, color, and load requirements. Manufacturers and suppliers, such as exporters in India, will provide tailored solutions based on your applications technical needs and conveyor specifications.Q: How does the powder coating or paint finish benefit the idlers?

A: The powder-coated or painted surface not only improves the idlers appearance but also provides enhanced corrosion resistance and durability, extending the products service life in harsh working environments.Q: What advantages do Bracket Roller Idlers offer for belt conveyor systems?

A: These idlers ensure stable belt alignment, reduce maintenance needs, and support heavy loads efficiently. Their customizable design and electric power compatibility make them a reliable, high-performance solution for modern conveyor systems.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Idler Roller Category

Roller Idlers

Price 1600.0 INR / Piece

Minimum Order Quantity : 50 Pieces

Warranty : 12 Months

Type : Belt Conveyor

Material : Mild Steel

Structure : Roller

Idler Roller

Price 3000.0 INR / Set

Minimum Order Quantity : 50 Sets

Warranty : 12 Months

Type : Belt Conveyor

Material : Mild Steel (MS) with powder coating

Structure : Other

Garland Roller Idlers

Price 2500.0 INR / Set

Minimum Order Quantity : 50 Sets

Warranty : 12 months

Type : Belt Conveyor

Material : Heavyduty steel, mild steel, stainless steel with powder or painted coating

Structure : Other

Heavy Duty Conveyor Idler Rollers

Price 600 INR / Set

Minimum Order Quantity : 50 Sets

Warranty : 12 Months

Type : Other

Material : Mild Steel, Stainless Steel ,Rubber ,UHMWPE ,HDPE , Plastic

Structure : Roller

Send Inquiry

Send Inquiry