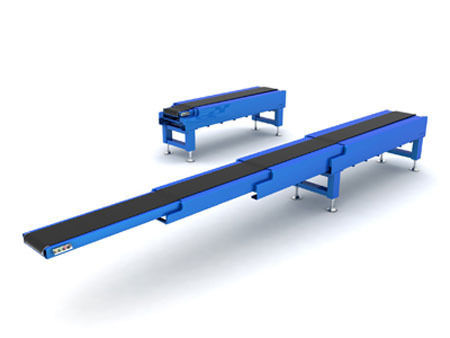

Rubber Belt Conveyor

Price 22000.0 INR/ Piece

Rubber Belt Conveyor Specification

- Thickness

- 5-20 mm (belt) Millimeter (mm)

- Belt Type

- Smooth, Cleated or Chevron Rubber Belt

- Surface Finish

- Painted / Powder Coated

- Features

- Durable construction, Low maintenance, High load bearing capacity, Easy installation

- Power Source

- Electric

- Material

- Mild Steel (MS), Stainless Steel (SS), with Rubber Belt

- Type

- Belt Conveyor

- Structure

- Other

- Belt Conveyor

- Other

- Product Type

- Belt Conveyor

- Roller Conveyor

- Other

- Vertical Conveyor

- Other

- Color

- Orange& Black

- Width

- 1 Meter (m)

- Resistant Feature

- Other

- Load Capacity

- 50-500 kg per meter Kilograms (kg)

- Voltage

- 220V / 380V Volt (v)

- Power

- 0.75 - 15 kW Watt (w)

- Speed

- 0.8 - 2.5 m/s m/s

- Usage & Applications

- Mining, Packaging, Agriculture, Manufacturing, Warehousing, and Material Handling Industries

Rubber Belt Conveyor Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 100 Pieces Per Month

- Delivery Time

- 1 Days

- Sample Policy

- Contact us for information regarding our sample policy

- Main Domestic Market

- All India

About Rubber Belt Conveyor

We are an ISO 9001:2008 certified firm engaged in manufacturing, exporting and supplying a wide range of Rubber Belt Conveyor. These Rubber Belt Conveyor are manufactured using quality tested components and pioneering techniques by skilled professionals. The provided Rubber Belt Conveyor can be bought from us in different specification at reasonable rates.

Key Points:

- Longer service life

- Low maintenance

- Easy to install

- Fine finish

Customizable Solutions for Every Industry

This rubber belt conveyor is engineered to adapt to your specific material handling requirements. With options for belt width, conveyor length, height adjustment, and vertical transport, it suits everything from light packaging tasks to heavy mining operations. The durable frame, supporting rollers, and selection of belt material grades ensure consistent performance across various settings.

Superior Durability and Resistance

Built with mild steel or stainless steel frames and high-grade rubber belts, the conveyor offers exceptional resistance to heat, oil, fire, and wear. The surface finish, available in painted or powder coated options, combined with belt thicknesses ranging 520 mm, ensures longevity and minimal maintenance. Its robust construction is suitable for demanding environments.

Efficient and Low-Noise Operation

Gear motor-driven mechanisms provide smooth, controlled operation with speeds selectable between 0.8 and 2.5 m/s. Designed for efficient energy use at 220V or 380V, and power ratings from 0.75 to 15 kW, this conveyor maintains noise levels under 70 dB, making it ideal for workplaces where quiet operations are prioritized.

FAQs of Rubber Belt Conveyor:

Q: How do I customize the conveyor length and belt width to fit my application?

A: You can specify the required conveyor length, up to 50 meters, and choose a belt width between 300 mm and 2000 mm. Our team supports custom configurations to suit your space and throughput needs, ensuring a tailor-made solution.Q: What types of materials is the conveyor suitable for transporting?

A: This conveyor is designed to handle a wide variety of materials, including bulk solids, packaged goods, and agricultural produce. The Grade N17 rubber belt and supporting structure allow for effective transport of items weighing from 50 kg to 500 kg per meter.Q: Where is on-site installation support available for this conveyor?

A: On-site installation support is available across India. Our experts assist with assembly, operational setup, and initial calibration to guarantee seamless integration into your facility.Q: What is the process for selecting belt type and idler configuration?

A: You can choose from smooth, cleated, or chevron rubber belts based on material characteristics and application. Troughing, impact, and return idlers are selected to optimize product support and durability for the intended load and operational environment.Q: How does the conveyor ensure durability in harsh working conditions?

A: The conveyor is constructed from mild steel or stainless steel with rubber belts that are heat, oil, fire, and wear resistant. These features, along with surface finishes like painted or powder-coated options, ensure it withstands demanding industrial conditions.Q: What are the benefits of using this conveyor in manufacturing and warehousing?

A: Adopting this conveyor streamlines material movement, increases efficiency, reduces manual labor, and enables safe handling of heavy loads. Its high load-bearing capacity and low-maintenance design significantly improve productivity and operational reliability.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Belt Conveyor Category

Belt Conveyor System

Price 35000.0 INR / Meter

Minimum Order Quantity : 18 Pieces

Thickness : 3 mm to 10 mm (belt thickness) Millimeter (mm)

Belt Type : Flat belt

Type : Belt Conveyor

Surface Finish : Powder coated/painted/SS finish

Incline Belt Conveyor

Price 75000.0 INR / Piece

Minimum Order Quantity : 1 Piece

Thickness : 3 5 mm Millimeter (mm)

Belt Type : Rough Top PVC Belt

Type : Belt Conveyor

Surface Finish : Powder Coated

Telescopic Belt Conveyor

Price 1000000.0 INR / Unit

Minimum Order Quantity : 1 Unit

Thickness : 38 mm Millimeter (mm)

Belt Type : PVC Belt

Type : Other

Surface Finish : Powder Coated

Send Inquiry

Send Inquiry