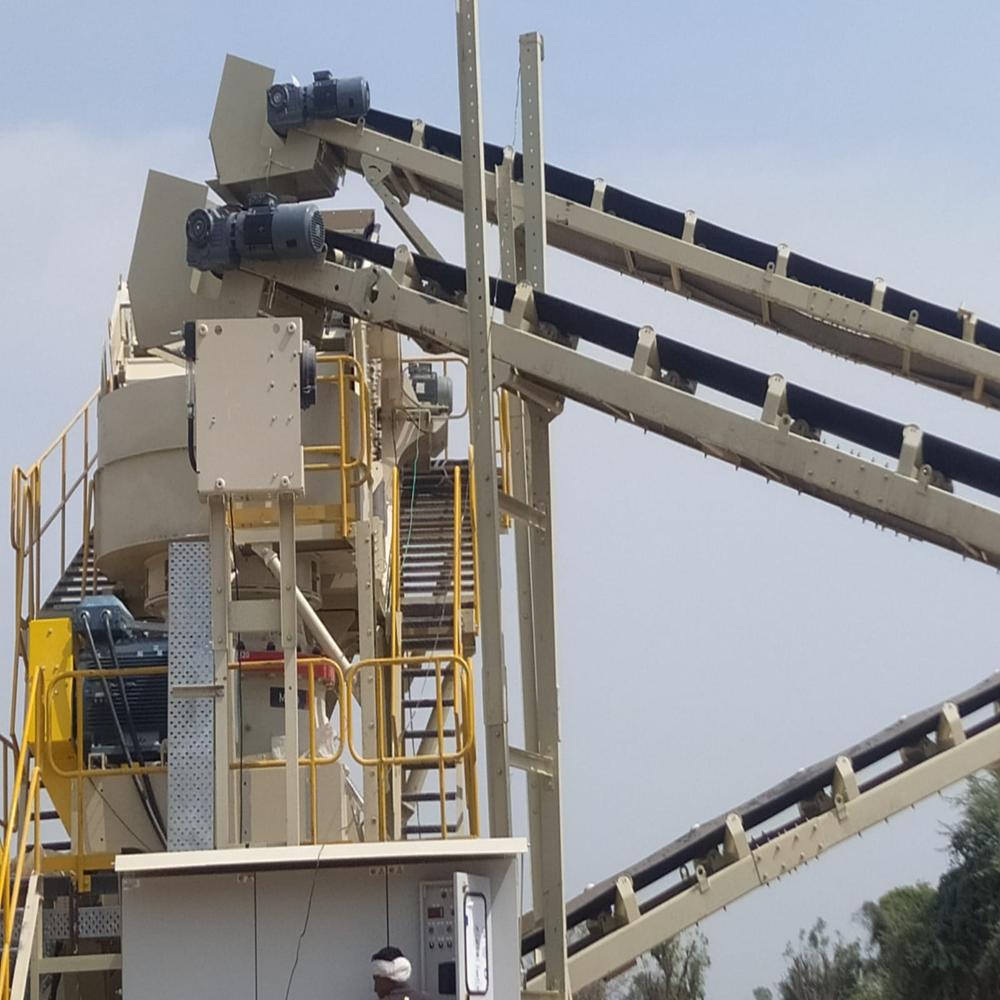

Belt Conveyor

Price 25000.0 INR/ Piece

MOQ : 1 Piece

Belt Conveyor Specification

- Belt Type

- PVC/PU/Rubber

- Rotation Type

- Straight/Inclined

- Equipment Type

- Belt Conveyor

- Lifting Speed

- Adjustable (0.5-1.5 m/s) m/s

- Features

- Corrosion resistant, Stable operation

- Motor Type

- AC Motor

- Control System

- Automatic/Manual

- Condition

- New

- Lifting Capacity

- Up to 200 kg per meter Kilograms (kg)

- Max. Lifting Load

- Up to 1000 kg Kilograms (kg)

- Max. Lifting Height

- Up to 3 meters Meter (m)

- Power Source

- Electric

- Power Consumption

- 1-5 kW Kilowatt (kW)

- Voltage

- 220-440 V Watt (w)

- Length of Belt

- 5-20 meters (customized as required) Meter (m)

- Feature

- Heavy-duty construction

- Warranty

- 12 Months

- Attributes

- Other

Belt Conveyor Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 100 Pieces Per Month

- Delivery Time

- 1 Week

- Sample Policy

- Contact us for information regarding our sample policy

- Main Domestic Market

- All India

About Belt Conveyor

We are an ISO 9001:2008 certified firm engaged in manufacturing, exporting and supplying a wide range of Belt Conveyor. These Belt Conveyor are manufactured using quality tested components and pioneering techniques by skilled professionals. The provided Belt Conveyor can be bought from us in different specification at reasonable rates.

Key Points:

- Longer service life

- Low maintenance

- Easy to install

- Fine finish

Adaptable to Diverse Industrial Needs

This customizable belt conveyor, available with flexible lengths and widths, meets a variety of industrial handling tasks. Its construction from mild steel or stainless steel ensures durability and adaptability to different working environments. With options for straight or inclined conveyors as well as fixed or swivel casters, it easily integrates into new or existing production lines, making it suitable for manufacturing plants, warehouses, and logistics centers.

Enhanced Safety and Durable Performance

Designed with features like emergency stops, robust side rails, and corrosion-resistant finishes, this conveyor guarantees safe and stable operation in demanding conditions. Operating quietly and smoothly, it supports up to 1000 kg of lifting load, with adjustable speed and lifting height. Its automatic or manual control system enables precise handling, minimizing downtime while maximizing productivity.

FAQs of Belt Conveyor:

Q: How can the belt conveyor be customized for specific industrial applications?

A: The belt conveyor offers customization in frame material (mild steel or stainless steel), belt width (300-1200 mm), length (5-20 meters), and direction (bidirectional). Additional accessories such as side rails, emergency stop, and various belt types (PVC/PU/Rubber) ensure suitability for unique material handling requirements.Q: What is the installation process, and where is on-site support available?

A: Installation is straightforward, with complete on-site support provided by our technical team across India. We assist with conveyor assembly, system integration, and commissioning to ensure optimal operation, regardless of installation complexity or location.Q: When should I choose a Variable Frequency Drive (VFD) option for speed control?

A: A VFD should be selected when precise speed or acceleration control is necessary for specific materials or varying workflow rates. This feature is especially beneficial for industries requiring flexible throughput or sensitive handling during operations.Q: Where is the drive system located, and how does it affect performance?

A: The conveyor offers flexibility with both end and center drive locations. The drives position is selected based on layout requirements and load distribution, ensuring smooth movement, stable operation, and efficient power consumption.Q: What benefits does heavy-duty construction and corrosion resistance offer?

A: Heavy-duty construction allows for stable, long-term operation even under frequent or high-load usage, with a lifting capacity up to 200 kg per meter. Corrosion-resistant materials, like stainless steel and powder-coated finishes, ensure minimal maintenance and longevity in harsh industrial environments.Q: How does the conveyor ensure operational safety?

A: Key safety features such as emergency stop buttons, side rails, sturdy frame designs, and low-noise operation (<70 dB) contribute to a safe working environment. These elements protect both personnel and materials during continuous industrial use.Q: What is the usage process, and how can the system be controlled?

A: The conveyor can be controlled automatically or manually, depending on the production requirements. Operators can adjust speed, lifting height, and direction using the available control system. Accessories like side rails and casters further simplify handling and transportation.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry